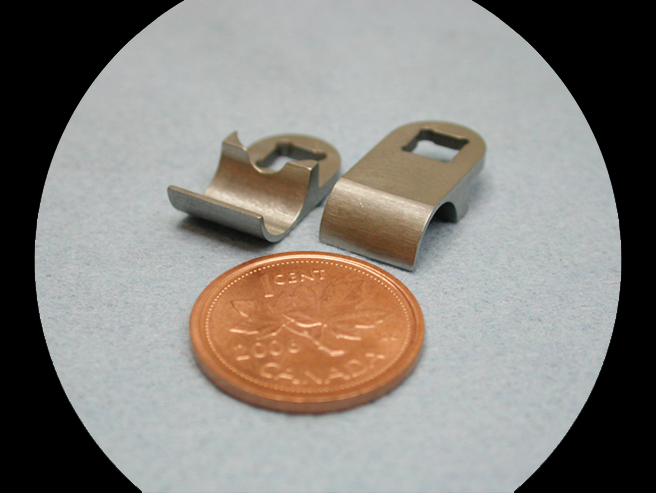

These are other surgical screwdriver parts.They were CNC milled from 303 stainless steel, form ground on the curved surface, and tumbled to finish. Quantity was 400 parts. These parts are also now metal injection molded from a mold built by Implant Mechanix Inc.

SIMPLE GANG FIXTURE:

Makes 10 parts at a time with minimal burring and no part distortion. The fixture was kept very simple because it was scheduled to retire after only 400 parts.

THE FIXTURE IN USE:

Machining time is about 12 seconds per part. The grinding wheel was shaped using a Diaform profile grinding wheel dresser.

Leave a Reply

You must be logged in to post a comment.