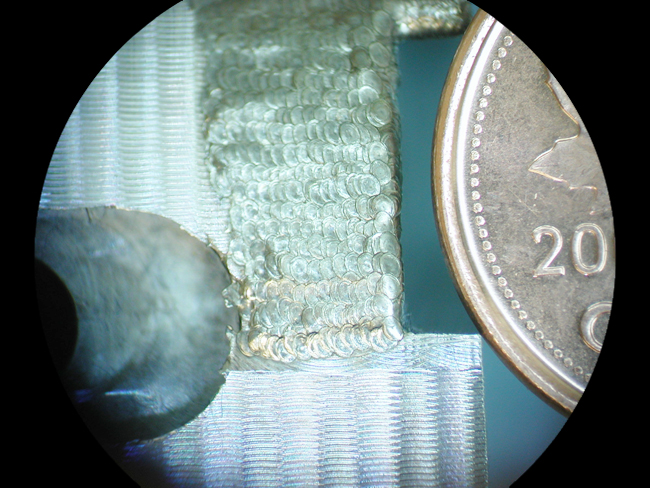

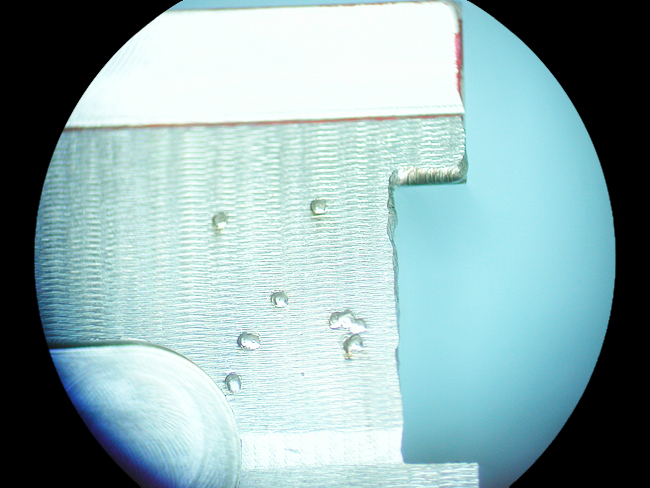

The corner was gouged with a cutter during rough machining. The repair must completely fill this large defect, but the heat of welding cannot be allowed to distort the part and shouldn’t disrupt the copper plug that seals a waterline in this part.

The material is 420M stainless at 52 RC.

This is about as big a weld volume as can be conveniently handled by laser micro welding. Bigger weld areas are better handled with TIG, but at the risk that the part will distort.

It is possible to do the rough welding using TIG and manage areas of distortion afterward, with the laser welder.

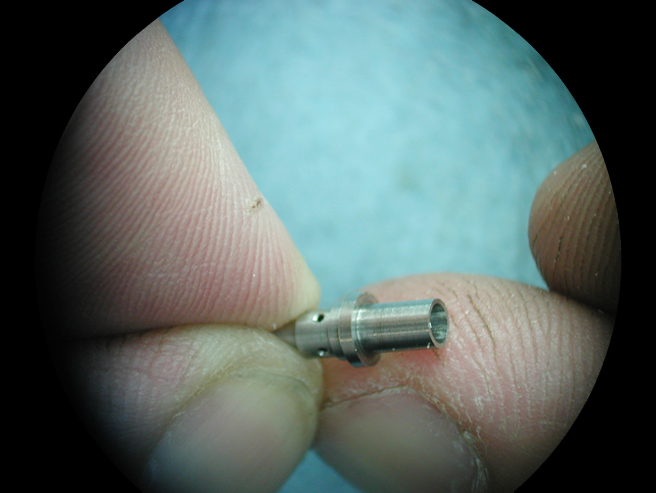

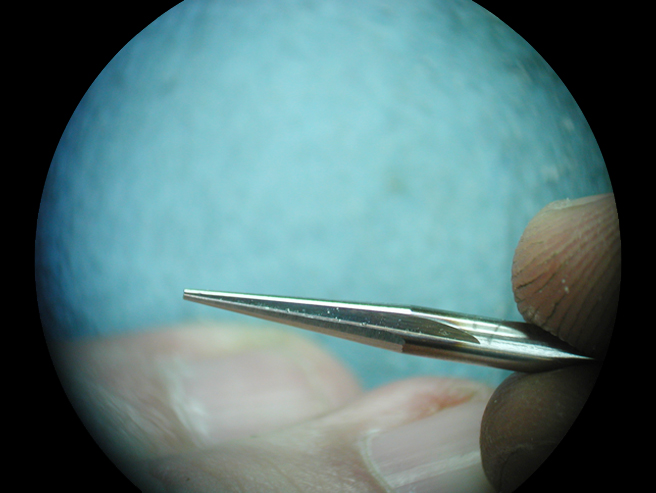

1. TOP VIEW: Note the huge number of individual welds required to fill this defect. (Each hemispherical mark you see, is formed by a discrete weld deposit using a 0.015” diameter 420 M stainless welding wire under argon gas coverage).

Recent Comments