This plastic part had a problem with localized flashing at the parting line, making it difficult to assemble to its mating part. A tiny nick on the parting line of the mold cavity was the source of the problem. The welded repair needed to be very delicate so it could be re-finished by hand without needing to go back into the EDM machine for re-burning.

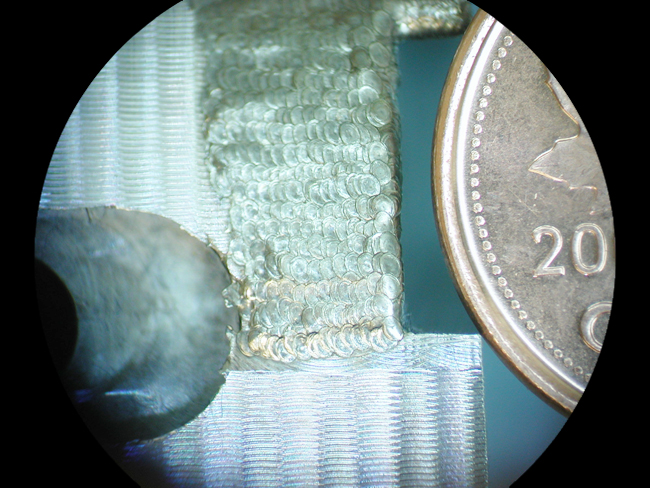

2. THE DEFECT IN THE MOLD CAVITY: The cavity is P20 Hi- Hard mold steel and the ding is circled in blue and red. Also visible laying across the penny is a bit of welding wire 0.005″ in diameter (about the thickness of a human hair). Welding wire in this size is very difficult to handle; it’s so fine you can’t feel it with your fingers. I have a special technique for managing wire this small: I use microsurgical needle drivers left over from my days as a dentist to hang onto it…that’s what caused the nicks you can see along its length.

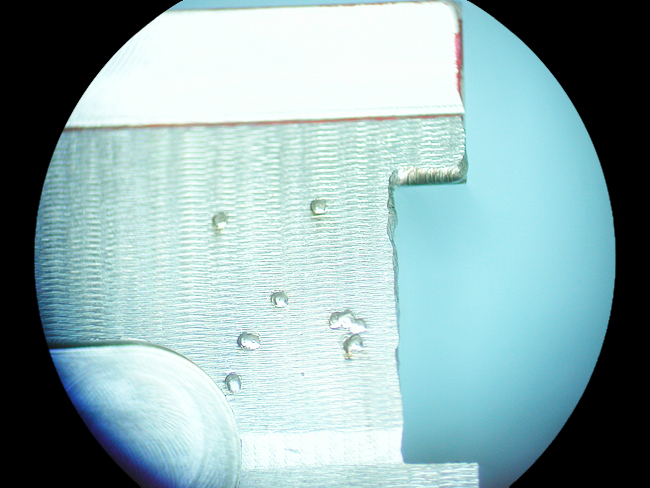

3. THE REPAIRED DEFECT: The challenge with these very tiny welds is not to burn away the corners of the cavity with the welding pulse, and to place the tiny, wiggly welding wire in the proper spot without blowing it out of position with the shielding gas. It takes a lot of practice to do this with confidence…I used up a good half of my 0.005″ wire stock just learning how to handle it, and I can’t have coffee before doing this class of repair welding.

Recent Comments