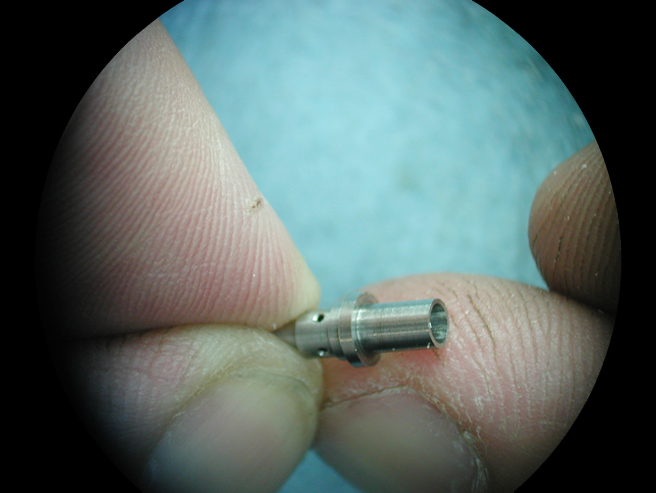

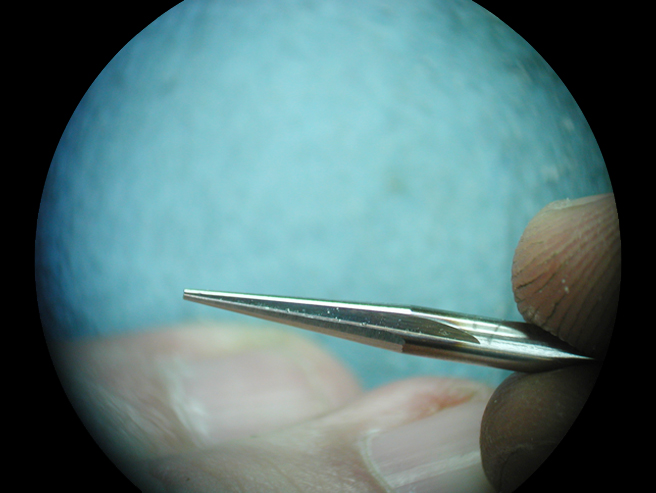

This is the tool used to make the hex bore in the bevel gear blank shown below. It is ground from High Speed Steel and is 0.090” (approximately 2¼ mm) across the flats at the big end. It is progressive; each tooth removes approximately 0.001” of material, and the guiding elements between teeth keep the broach perfectly centered.

Recent Comments