Category: Precision Machining

Shown are a set of 316 stainless steel parts for a probe. The deep precision bores and tight tolerances are challenging but straightforward. The threaded spindle is 3/8″ diameter and the part on the extreme left has angled internal passages that required the operation sequence to be carefully pre-planned. There is a laser welded wire screen visible on the front end of the second part from the left. The longest part is approximately 6″ long.

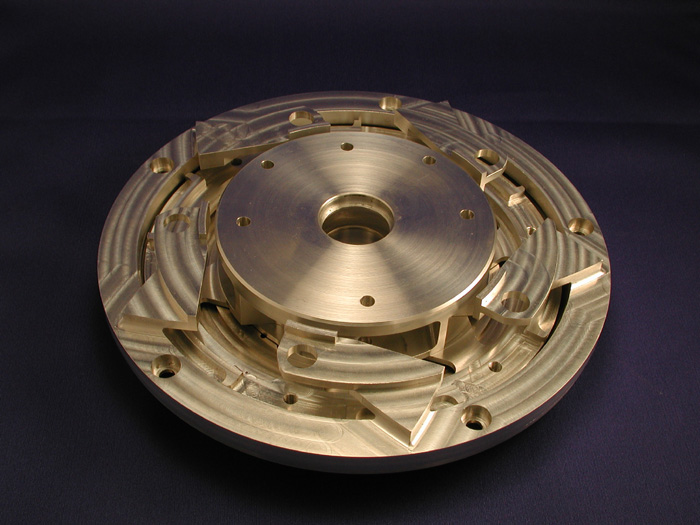

Shown are a pair of parts used in a torque clutch for a surgical instrument. These are made of 17-4 PH stainless steel and required turning, milling and sinker EDM to complete. The biggest part is just under 1 inch in diameter.

Here is an assembly of thin walled parts that form part of the casing of a bicycle transmission. There are 4 parts in the assembly and it is about 7″ in diameter. The thinnest parts are less than 1/8″ thick, and were challenging to make because of the precison requirement on these distortion prone parts.

Here is a tiny prototype bevel gear for the surgical screwdriver featured on the homepage. It is hardened 17-4 PH stainless steel and is ¼” diameter (about 6.5mm).It was completely fabricated in-house, including CNC turning, broaching, and CNC sinker EDM on the teeth.

200 of these parts were initially run in our plant: the part is now made in a metal injection mold built by Implant Mechanix Inc.

Recent Comments